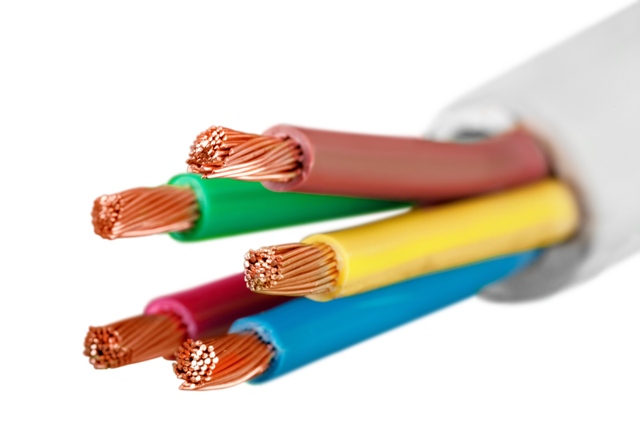

Power cables are the basic components of any electrical system. There are different types of cables that are available in the market. The choice of which specific cable types should be used for specific purposes is based on several factors, the most important of them being the technical specifications of the functions.

As much as you may be conversant with electric cables, it is possible that there are things about power cables that are new to you. Here is a brief outline of some of the things about power cables:

-

Copper is not always a better conductor than aluminum

Many people believe that copper is a far better conductor of electricity than aluminum at all times. This is inaccurate. When it comes to matters of what type of conductor is better between these two metals, there are many factors that need to be taken into account.

The most important one of them is that conductivity in relation to cable wires is not merely a function of the measure of resistivity but rather a unique combination of the size of the cables and the insulation material that is used. Hence, in cases where super-high voltages have to be used over long distances, it becomes economical for one to use aluminum cables as opposed to copper ones.

-

The cable current capacity is affected by different factors and does not remain stable

It is common to hear people talk of the possibility of their current cable capacity to remain stable forever. Incidentally, this is a common misconception about electrical cables that people hold.

However, the truth of the matter is that the cable current capacity changes all the time and does not remain stable over the lifetime of the cables. These changes are usually caused by factors such as the prevailing ground or air temperature, the actual manner in which the laying has been carried out and the depth at which the cables have been laid.

-

New power cables do not last as long as people expect them to

There are several reasons as to why newly installed power cables do last as long as people expect them to. The first one is that since there are many manufacturers of electric cables, it is highly unlikely that all the power cables that you install will last for a specific period of time.

The second one is that there are many different types of power cables. A specific type of power cable is defined in terms of its capacity, durability, usage and other industry-specific characteristics.

The third one is that the extent to which a cable lasts heavily relies on the manner in which the installation is done. A poorly done installation may significantly shorten the life of a cable.

-

Cable armor is not used to protect the cable against possible physical impacts

The armor that is used on your cable is not meant to help in protecting the cable against any chances of physical impact. On the contrary, if any type of power cable is exposed to a form of physical stress, it is possible that the damage to the cable arising from the impact is likely to be aggravated by the armor!

This is because the cable armor used on all types of cables is usually made up of steel tape or steel wire. These materials are expected to increase the tensile measure of the cables and not to protect the cables from physical impact.

-

The cable armor cannot protect electric cables from moisture

It is commonly held that for any power cable types, the inclusion of the armor makes it possible for the cables to be used in moist areas. Once more, it should be emphasized that the armor is not meant to protect the cable from the water. Therefore, exposing armored cables to water may easily lead to the destruction of the armor and lead to the exposure of the actual cables over time.

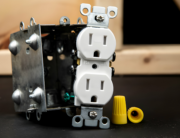

The last thing that you need to consider is related to safety. You should remember that a faulty installation of cables can easily lead to an accident. Therefore, before you carry out any electrical installation project, it is recommended that you contact your local building inspector. It is also best to get the project inspected for compliance with local regulations and codes once it is complete.

Call D & F Liquidators Inc. today and let us discuss your options with you.

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.