Job and industry sites are usually prime locations for potential electrical fire hazards. Fires are quite common on construction sites and are extremely risky as they cause serious injuries and can be life threatening as well. Fires on the construction site also pose a serious risk to the general public as well as the property around a jobsite which can threaten the general public as well as any other properties near your site. This unforeseen type of damage can increase your costs and be expensive to your company.

Studies show that more than 5,000 workers are fatally electrocuted at work every year and 40% of these workers were from the construction industry. Even though all of these electrocutions are not fatal, the long-term effects can be pretty severe due to the severe burns that carry risks of infections, permanent nerve damage, and neurological disorders.

The awareness of electrical fire hazards on construction sites has grown through the years as frequent incidents of fires and accidents can’t be overlooked. Recent improvements in general construction site procedures and safety measures have already started making a difference but a lot more can always be done.

Here is how you can reduce the chances of any electrical hazards happening on your site with these 5 electrical safety tips

-

Prevent Accidental Electrical Contact

Most if not all job and industry sites have a lot of different crews working on them at the same time. Here are 2 simple precautions that you can take to avoid any accidental electrical contact:

- De-Energize Your Electrical Components

If you are not using an electrical system then it simply doesn’t have to be energized. It is advisable that you keep the power shut off till you want to use it. - Create a Barrier

Make sure that you install insulation equipment like rubber mats and conduit around your electrical components. Put up signs to let your workers know of the areas which have electrical hazards.

- De-Energize Your Electrical Components

-

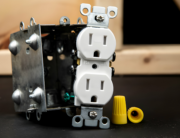

Always Plug into a GFCI

This is necessary at every plug point on your job site which is associated with your site’s temporary electrical supply- right down to the extension cords. Make sure that you only have the GFCI receptacles installed and also keep some portable GFCI’S on hand in case you need to do any extra grounding.

-

Use Approved Equipment Only

Only use proper equipment to prevent contact with the electrical current when you work around energized components. Use properly insulated tools that will prevent the flow of electricity if they come into contact with a live wire.

It is best to hire certified electricians as they will know what equipment is approved and how to best install it.

-

Wear the Right Protective Gear

Make sure that all of your workers are equipped with protective gear to reduce their risk of being exposed to electrical hazards. Ensure that your workers wear properly insulated head protection to avoid contact with overhead wires that is approved. Your workers will need face protection and eye protection to minimize any injuries caused by arc blast. Wearing insulated hand protection is also very important to stop the flow of electric current if contact is made with energized equipment.

You should also create an emergency contact list as well as keeping a first aid kit handy which is always available to your employees.

-

Temporary Electrical Service Safety

Sometimes, your construction site might need a temporary electrical service to be installed near the building till it has its own electricity system. Make sure that the temporary service is well protected from any rainy weather and ensure that it should never become overloaded as this may be dangerous.

We at D&F Liquidators believe in safe electricity and have been working towards providing the best services. Don’t wait for an emergency, contact our professionals today!

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.