Limit switches, as the name suggests, are precision switches that are designed to work as limiting devices. The switch is typically snap-action and designed to sense the presence, absence, or be triggered by an excess or lack of physical contact at the position where it is installed.

The flexibility and adaptability of limit switches to different tasks and environments has made them very popular as components of conveyor belt systems.

Classes of Conveyor Belts and their Applications

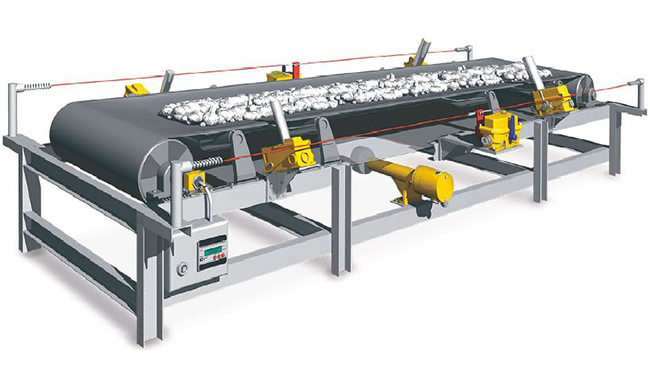

Industrial conveyor belts are considered to be amongst the greatest inventions for boosting production, as well as reducing time, costs and manpower requirements. They are commonly used in production, mining, assembly lines and just about every major industry or sector today.

They typically consist of a number of pulleys that rotate under a continuous belt. Some of these pulleys are powered and they drive the belt, keeping any material on top continuously moving towards its destination.

Conveyor belts can be broadly classified into two classes

-

General Material Handling Conveyors

These conveyors are used for transporting smaller volumes of material like packaged goods, or lighter materials like boxes.

-

Bulk Material Handling Conveyors

These are heavy duty conveyor systems which are designed to carry heavier loads or bulky materials, like industrial and agricultural goods.

Different Kinds of Limit Switches Used in Conveyor Belts

While conveyor belts can tremendously increase efficiency, they are prone to jamming from over-loading unless the correct safety measures are put in place. Limit switches help prevent this by measuring the height or number of individual products passing through the conveyor system. In case the switch senses an object that may cause an obstruction, it shuts the system down to prevent damage or spillage.

Depending on the environment and purpose, there are a variety of limit switches which can be used in conveyor systems:

-

Heavy Duty Limit Switches

Heavy duty limit switches are frequently installed on conveyor systems which are located in harsh environments, both indoors and outdoors. They are very reliable for indicating the position of materials to the system controls.

Applications – Based on the configuration, heavy duty limit switches can be used for counting individual items traveling on the conveyor, or even for ensuring that each one is in the right position and correctly aligned.

-

Safety Switches

Automated safety measures are essential for safe operations, but manually operated safety switches are also equally important. Safety switches use a cable-pull system, which is composed of a snap-action switch linked to a cable with a grip at the end.

Applications – Safety switches are extremely safe to use, providing an extremely reliable and highly visible device to immediately stop a conveyor. In case a situation arises where operators need to quickly stop the conveyor, they can simply yank the cable pull.

-

Hazardous Location Limit Switches

Conveyors are also quite adaptable to different environments, including some very harsh ones. Hazardous location limit switches are similar to heavy-duty ones, except they are housed in enclosures which are sealed and rated for use in different hazardous locations. These could be above-ground, outdoors, or in environments that are prone to explosions, such as fuel or grain handling.

Applications – Hazardous location limit switches are used in applications where they may be exposed to hazardous environments or potentially dangerous situations which could trigger an explosion from electrical discharges, sparks and other external factors.

-

Safety and Hazardous Location Switches

Conveyor belts in hazardous locations are often automated, with a centralized control system, but some of them do require human intervention. Safety and hazardous location switches are similar to safety switches, but they are rated for use in hazardous locations.

Applications – Safety and hazardous location switches are used in environments where suspended particles, gas or other compounds are present in the surroundings. These switches can be tripped in case a potential for danger is spotted, without increasing the risks of an explosion or other disaster resulting from operating the switch.

Other Uses for Limit Switches in Conveyor Belt Systems

There are also many other uses of limit switches on conveyor belts, depending on the kind of material being handled, the environment where they operate, and the particular needs of the industry where they are used.

They can, for example, be used alongside the conveyor belts themselves, to ensure that materials or packages that are traveling over the belt are correctly positioned and not protruding beyond a certain point. In case of misaligned objects, the limit switch will be triggered and it sends a signal to the controller which halts the progress of the belt, so workers can correct it before continuing.

Since conveyor systems are themselves often designed according to custom requirements, a combination of one or more types of limit switch can be included as part of the design.

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.