Any electrical construction project or job site using electrical equipment faces a risk of damage, injury and even fatalities. Dangerous situations can escalate if they aren’t curbed in time, particularly in high-risk applications such as mining, which is considered the most risky setting for using electrical power. Here’s why:

- The electrical fatality rate in the mining industry is estimated to be as much as 8-12 times that of other industries.

- In the ten years between 2003 and 2013, almost 200 out of close to 2000 electrical-related workplace deaths occurred in mines.

- Only one fatality occurs for over 200 non-electrical mining injuries, but there is one fatality for every 22 electrical-related injuries in mines.

- 3 out of 4 mining-related injuries happen while using or coming into contact with electrical equipment, lighting, wiring, conduit fittings and other components.

- Environmental hazards and mining by-products can cause major explosions or cave-ins from even the slightest miscalculation, minor accident or malfunction!

Handling Construction Electrical Material in Mines

-

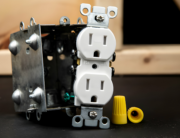

Installing an Electrical System

Follow these measures to minimize risk during electrical system installation in mining zones:

- Properly grounding the system is crucial.

- Use heavy duty electrical wires and cables, power distribution systems and other construction electrical materials approved for use in mines

- To avoid overheating, sparking, arcing and electrical shock, ensure that connectors and conduit fittings are insulated and set up to avoid high resistances.

- Use enclosures or sheathing to protect electrical conductors and insulators against damage, especially in flammable environments.

-

Using Equipment

Electrical wires for machinery run along mines, increasing the risk of electrocution, tripping, etc., so take these steps to reduce hazards:

- Equipment compatibility is critical, since using incompatible construction materials or connectors can lead to accidents and injuries. Use clear markings, keyway coding or padlocks where unrelated plugs and sockets are coupled.

- Where possible, use low voltage equipment at or below 50 V ac/120 V dc. Take special precautions while using high voltage equipment, and ensure that workers use dc handheld equipment in damp or highly conductive areas.

- To protect the integrity of conductors and insulation, ensure that protective devices, cable coverings and conducting screens are properly sealed and attached. This minimizes contamination as well as corrosion in damp areas.

- Use bolted or restrained plugs and sockets to prevent system changes being made by unauthorized workers while operating equipment.

-

Equipment Damage/Emergencies

Here are some ways to minimize safety risks in case of electrical emergencies or equipment damage:

- Upon locating a defect, take immediate action. Ensure there is no electrical power source attached to damaged equipment before starting repairs.

- If damaged or defective equipment cannot be repaired right away, it should be isolated, taken out of service, labeled clearly and locked up safely.

- Place emergency equipment at regular intervals throughout the mine, and ensure that workers are trained on using it in case of an emergency.

- Use a back-up electrical power source for critical support systems, to ensure they keep running even after the main power supply gets cut off.

For higher safety and efficiency in mines, electrical systems and construction electrical material need to be built and installed properly. At D&F Liquidators, we can provide you with high quality electrical supplies for use in heavy duty systems. Get in touch with us to discuss your needs today!

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.