If you work in hazardous locations and conditions, you would understand the need to promote safety and ensure that the risk of explosions is reduced. It is crucial that you eliminate one or more component of the ignition triangle to minimize the chances of an explosion. The 3 protection methods listed below are widely used in hazardous locations, in the process control industry:

- Containment Method

- Energy Limitation

- Avoidance

Before we delve a little deeper and understand these techniques, let’s take a quick look at the role electrical enclosures.

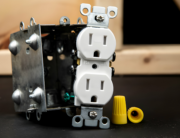

Electrical enclosures are cabinets containing different electrical components such as switches, sockets, plugs, knobs, transformers and controls. These keep the surroundings safe from any kind of electrical hazard. Such enclosures are resistant to spark and shock and they have a high tolerance to extreme temperatures. They must be used in hazardous locations as they keep an interior explosion from spreading to the external environment and damaging life and property. Let’s see how they are relevant in the Containment method of protection:

- Containment Method: This method is used to contain an explosion within the equipment enclosure. The containment method restrains the explosion to a well-defined area so that propagation of the explosion in the surrounding areas is avoided. This method is often used with spark-producing parts like control boards, switch gears or transformers. Explosion-proof enclosures are based on this method. Ensure that the explosion-proof container has the symbol (Ex d). These containers should meet the following requirements:

- All the enclosure joints that lead to the outside atmosphere must be flameproof

- The enclosures must have sufficient strength to withstand an internal explosion without any kind of permanent damage, deformation or rupture

- The surface temperature of the enclosure must never exceed ignition temperature of the ambient gas-air mixture

- The thickness, impact strength, corrosion resistance and porosity of the explosion-proof material used in such enclosures must be considered while selecting them

- Energy Limitation: Another common method is to remove sufficient energy from the escaping gases so that the energy levels are below the minimum ignition energy levels of any flammable gases and combustible dusts in the ambient atmosphere. One of the most common energy limitations is ensured by designing equipment that is intrinsically safe or by using inherently safe barriers. This kind of equipment will have the symbol (Ex i) on it.Intrinsically safe (IS) equipment helps in preventing explosions by limiting the release of sufficient electrical energy which can potentially ignite the explosive gases in the atmosphere under normal conditions. Other advantages of using IS equipment include:

- It is easier to maintain and repair

- Involvement of operator is minimum to maintain a safe system

All IS devices are assigned the maximum current, voltage, inductance, capacitance and power supply limits. Based on the magnitude of these parameters, you can determine the level of energy storage that is allowed in these devices.

- Avoidance: The avoidance method provides protection against explosions by using equipment that does not spark or arc in normal services. This prevents the ignition source from ever occurring. The equipment used for this method can be designed to have increased safety designated by (Ex e) or designed to be non-sparking (Ex n).Increased safety (EX e) is the more commonly used method of protection. The manufacturers design the components to reduce the likelihood of ignition substantially by:

- reducing and controlling the working temperatures

- increasing the insulation effectiveness

- ensuring strong electrical connections

- reducing the probability of contamination by access to dirt and moisture

- On the other hand, special precautions are taken with wiring and connections in non-sparking (Ex n) equipment to increase its reliability. Equipment rated with (Ex n) does not produce sparks, arcs or hot surfaces in normal operation. This kind of equipment is commonly used with three-phase induction motors in hazardous areas.

Of all the three commonly used protection methods, intrinsic safety is the most preferred for reliability and safety reasons. Moreover, it is also the most economical method when it comes to installation and maintenance.

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.