NEMA or the National Electrical Manufacturers Association has developed rating standards for electrical enclosures to ensure safety, compatibility and proper function of electrical products. These ratings provide the standards that help in defining the types of environments in which various electrical enclosures can be used. NEMA ratings frequently indicate a fixed enclosure’s ability to withstand certain environmental conditions.

NEMA ratings are mainly applied to fixed enclosures and are rarely applied to mobile devices. They have extremely stringent testing requirements to verify if the enclosures can be protected from external ice, oil immersion, corrosive materials, dust, water, etc. Each NEMA rating has different specifications; however, all of them are designed to protect electrical components, personnel and property from damage.

Importance of NEMA ratings

If you use any kind of electrical enclosure, it is important that you check its NEMA rating before installing it. There are a number of reasons why it is important to do so. Let us look at three reasons why NEMA ratings are important.

- NEMA ratings help you ensure that the electrical enclosures have proper compatibility, safety and functioning standards.

- It allows you to determine which enclosure is suitable for the environment you want to install it in.

- The 600 standards published in technical papers and application guides help you understand all about electrical product safety and function.

Certification of Enclosures under NEMA Ratings

NEMA just defines and publishes enclosure standards. It does not test the electrical products and neither is it affiliated with testing laboratories. The manufacturers’ compliance with the NEMA standards is entirely voluntary. While some manufacturers choose to self-declare their compliance, there are some who prefer to use a third-party testing and certification. This certification helps the manufacturers provide tangible assurance to their customers that their products will perform as expected after they are bought. Additionally, NEMA also provides a list of testing laboratories and certification bodies that perform this service.

Common NEMA Enclosures

-

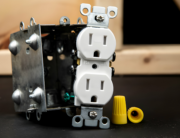

- NEMA Type 1

-Most commonly used for indoor commercial applications that include switches, junctions, utility boxes, etc.

-NEMA 1 enclosures require the least amount of protection and it provides a degree of protection to personnel against access to hazardous parts

-Used to provide a degree of protection of the equipment inside the enclosure against entry of solid foreign objects such as falling dirt and dust

- NEMA Type 3

– Commonly used for indoor or outdoor use for providing a degree of protection to personnel against access to hazardous parts

– This rating provides a degree of protection against windblown dust and falling dirt

– Type 3 rating shows that the enclosure is dust-tight, rain-tight and sleet-tight and that it will also be undamaged by the external formation of ice on the enclosure.

- NEMA Type 3R

– Enclosures with this rating can be used for indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts

– They are designed to be weatherproof and withstand rain, snow, windblown particles and ice formation on the enclosure

– Mainly used in meter cabinets, filtered fans and utility boxes

- NEMA Type 4

– Mostly used in industrial applications such as wiring enclosures, hydraulic controls and operator consoles.

– Enclosures with Type 4 ratings are watertight, and provide protection against rain, sleet, snow, ice formation, splashing or hose directed water

– These enclosures must use a closed-loop cooling system so that contaminants do not enter the unit

– Both air to air heat exchangers or air conditioners can be used for NEMA Type 4 enclosures, based on the ambient temperature surrounding them.

- NEMA Type 4X

– Similar to the specifications for NEMA Type 4 enclosures, the Type 4X designation offers additional protection against corrosion

– Enclosures with this rating are mostly found in marine environments, paper manufacturing applications, industrial food processing, oil and gas drilling, refining and processing, and water treatment

– Depending on the ambient temperature, both air to air heat exchangers and air conditioners are suitable closed-loop cooling systems for a NEMA Type 4X enclosure

- NEMA Type 12

– Enclosures with this NEMA rating are designed to be dust-tight for indoor use, but not necessarily as watertight. However, they do provide enough protection extreme washdown environment with high-pressure hoses

– A closed-loop cooling system is required for NEMA Type 12 electrical enclosures

Are you working on a big project that calls for different electrical enclosures with NEMA ratings? Contact us at D & F Liquidators. We have a huge selection for you to choose from, all at great prices too!

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.