Table of Contents

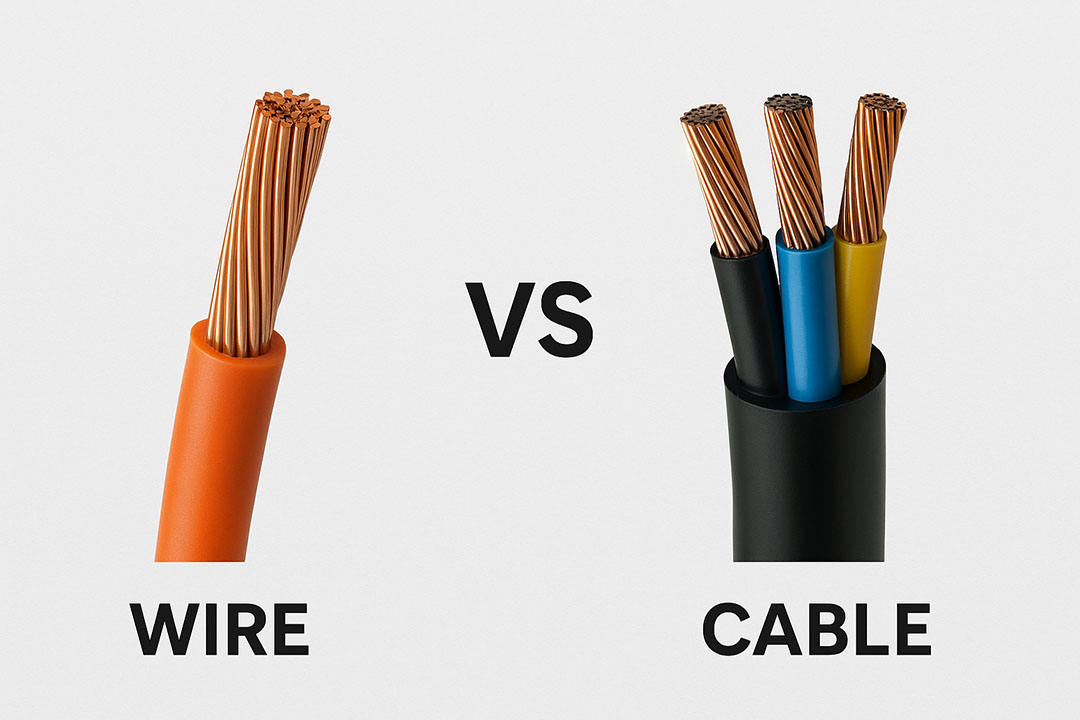

Wires and cables serve as the foundation for contemporary electrical systems, guaranteeing the smooth operation of electricity, data, and communications in buildings. Nonetheless, a widespread misunderstanding still exists: the idea that “wire” and “cable” are the same.

Although both are essential to the infrastructure, it is crucial to comprehend their distinctions. Understanding the differences between cable and wire can significantly improve your project management abilities, ultimately leading to safer and more effective usage.

What is a Wire?

When discussing electrical components, the term “wire” refers specifically to a single conductor, primarily made from materials such as copper or aluminum. Wires are essential conduits for carrying electrical current and can be categorized into distinct types of wire based on their intended use.

For example, you have THHN wire for industrial applications, Romex (NM cable) for residential wiring, and many specialized wires designed for heat resistance, flexibility, or specific conductivity needs.

The versatility and simplicity of wires make them a cornerstone in any electrical system. However, they require correct selection based on the specific application to ensure optimal performance without compromising on safety.

What is a Cable?

A cable is a group of several wires that have been bundled together. Additional parts like insulation and shielding are frequently included in cables to protect the internal wires and improve the overall structure’s ability to transport current, provide mechanical protection, and maintain signal integrity.

From telecommunications to electrical distribution, this wire combination enables cables to operate more efficiently in a variety of applications.

There are many different types of cables: multi-conductor cables serve a variety of electrical systems, fiber optic cables are used for fast data transport, and coaxial cables are used for TV signals. Every kind of cable is designed to have particular structural qualities that satisfy various operational requirements.

What is the difference between Wire and Cable?

While cable and wire are often used interchangeably, the main difference between Wire and Cable is that a wire is a single conductor, typically made of copper or aluminum, while a cable is composed of multiple wires bundled together, often with insulation and shielding. Essentially, a wire is a component of a cable, and a cable provides greater current-carrying capacity, mechanical protection, and signal integrity due to its multiple conductors and protective layers.

There are a number of other noteworthy distinctions in Wire vs Cable, including the following:

-

Construction

- Wire: Made up of several twisted strands or one solid strand.

- Cable: A cable is made up of multiple wires that have been connected and are frequently shielded by an outer sheath.

-

Flexibility

- Wire: Solid wire types, in particular, are typically less flexible.

- Cable: Because it has several strands that may bend without breaking, it is more flexible.

-

Durability

- Wire: Wire may be robust, but it frequently lacks further layers of protection.

- Cable: Provides stronger insulation and sheathing for increased durability.

-

Insulation

- Wire: Insulation is minimal and is usually only present in specific types.

- Cable: Comes with comprehensive insulation designed to handle various environmental factors.

-

Current Carrying Capacity

- Wire: Higher capacity based on gauge size and material.

- Cable: Limited current capacity due to multiple conductors.

-

Weight

- Wire: Generally lighter and easier to handle.

- Cable: Can be heavier because of its multiple components.

-

Heat Resistance

- Wire: Not very resistant to heat.

- Cable: Frequently made to withstand higher temperatures.

-

Safety

- Wire: It might not have the safety measures required for intricate installations.

- Cable: Usually has safety features, especially for high-voltage applications.

-

Applications

- Wire: Perfect for simpler electrical systems.

- Cable: Ideal for more intricate arrangements, including multiple wires.

-

Installation Simplicity

- Wire: In simpler applications, it is easier to install.

- Cable: May call for certain methods or equipment for installation.

-

Signal Interference

- Wire: Long-range susceptible to interference.

- Cable: Made to reduce interference, especially in communication and data.

-

Mechanical Strength

- Wire: Does not have the mechanical defense that cables provide.

- Cable: Offers mechanical durability for use in harsh conditions.

-

Lifespan

- Wire: Shorter lifespan in varied conditions.

- Cable: Longer lifespan due to additional protection and insulation.

-

Cost

- Wire: Generally less expensive.

- Cable: Higher initial cost but often proves more economical in long-run applications.

-

Usage Environment

- Wire: Best for simple, less demanding conditions.

- Cable: Perfect for harsher environments due to enhanced protection.

Table: Cable vs Wire

| Feature | Wire | Cable |

| Definition | A single electrical conductor, usually made of copper or aluminum. | A group of two or more insulated wires wrapped together in a protective sheath. |

| Construction | Made of a single strand or multiple strands of metal. | Contains multiple conductors, each insulated, enclosed in an outer protective layer. |

| Flexibility | Less flexible, especially if solid. | More flexible due to multiple insulated wires. |

| Durability | Less durable, prone to damage in harsh environments. | More durable, with additional insulation and protection. |

| Current Carrying Capacity | Wires have a higher current-carrying capacity per conductor due to less insulation. | Cables have multiple conductors, but insulation may slightly reduce current-carrying capacity per conductor. |

| Insulation | May or may not be insulated. | Always insulated with protective layers. |

| Weight | Lighter in weight due to a single conductor. | Heavier because of multiple conductors and insulation layers. |

| Heat Resistance | Wires heat up faster as they have less insulation. | Cables are designed to resist heat buildup due to insulation. |

| Safety | Less protection against electrical hazards. | Better safety due to insulation and shielding. |

| Applications | Used for simple electrical connections, house wiring, and small circuits. | Used in complex electrical systems, data transmission, and industrial applications. |

| Ease of Installation | Easier to install in simple applications. | More complex to install, especially in industrial and underground applications. |

| Signal Interference | More prone to interference as it lacks shielding. | Shielded cables reduce electromagnetic interference, making them ideal for data transmission. |

| Mechanical Strength | Lower mechanical strength, more prone to breakage. | Higher mechanical strength, designed to withstand environmental stress. |

| Lifespan | Shorter lifespan, especially in harsh conditions. | Longer lifespan due to protective coatings and insulation. |

| Cost | Generally cheaper than cables. | More expensive due to added insulation and multiple conductors. |

| Usage Environment | Commonly used for short distances and small electrical projects. | Suitable for long distances, heavy-duty applications, and communication networks. |

Cable vs Wire – What to Use?

Hopefully, by now, the difference between wire and cable is clear to you. Are you thinking about what could be the right component for your next project? A number of considerations should influence your choice between wire and cable for your particular requirements. They are:

- Application Prerequisites: Consider your project’s particular electrical or communication requirements.

- Current and Voltage Ratings: Find out how much power is needed to guarantee safe functioning.

- Needs for Durability and Flexibility: Determine whether your installation requires options that can be bent or more flexible.

- Environmental Aspects: When making your choice, take into account factors like moisture content, temperature extremes, and chemical exposure.

- Cost Factors: Compare the possible long-term savings with the upfront costs.

- Safety Standards and Regulations: To avoid dangerous circumstances, always follow local and federal rules.

In summary, while both are integral components of electrical and communication systems, understanding the key differences between wire and cable is essential for efficiency and safety. Wires serve well in straightforward installations. In contrast, cables offer distinct advantages, especially in complex systems.

Choosing the right electrical product is not only about cost or convenience; it is about ensuring that your project’s infrastructure operates effectively and securely for years to come.

Ready to enhance your home’s safety? D&F Liquidators has the electrical supplies you need.

Frequently Asked Questions (FAQs)

Which is better, cables or wires, for electrical wiring?

The application determines this decision. For simpler installations, wires are frequently chosen, but cables are usually superior for more intricate systems that need more security.

Is it possible to utilize a wire in place of a cable?

It is OK in certain situations, although cables are usually advised for greater power applications or longer distances in order to assure safety.

Which materials make up the majority of wires and cables?

Copper and aluminum are the most common conductive materials. At the same time, PVC, rubber, and other polymers are frequently used to make insulation.

Why do communication systems prefer cables?

Cables often reduce signal interference and are made to transmit data efficiently, especially when you use cables such as fiber optic and twisted pair cables.

What kind of wire is ideal for wiring a house?

Solid copper wire is frequently used for wiring a house because of its superior resilience and conductivity.

Do cables need to be maintained more than wires?

Because they are better protected, cables often require less maintenance, yet fixing a damaged cable can be more difficult.

How do I decide between wire and cable for my project?

To select the most suitable option, take into account elements like power requirements, flexibility, insulation demands, and safety standard compliance.