Table of Contents

If you are a homeowner or manage a property, you’ve likely come across electrical conduits while doing renovations or maintenance work. But what exactly are they, and why are they important? It’s not just about keeping wires neat. It’s about safety, durability, and code compliance.

This guide walks you through what an electrical conduit is, its types, uses, pros and cons, and how to choose the right one for your project.

What is an Electrical Conduit?

An electrical conduit is a durable tube or pipe that protects and routes electrical wiring in a building or structure. It acts as a physical shield against damage, moisture, chemicals, and other environmental hazards. Available in both metallic and non-metallic forms, conduits help ensure that wiring systems remain safe, organized, and up to code.

Think of it as a guardrail for your wires, guiding them safely from point A to B while shielding them from harm.

What is Electrical Conduit Used for?

Protecting wiring against physical impact, moisture, heat, and chemical exposure is the primary objective of employing an electrical conduit. Additionally, keeping cables insulated and protected helps prevent electrical shocks and fires.

Conduits must frequently adhere to safety regulations and requirements in both residential and commercial settings.

Types of Electrical Conduit

Before you install anything, it’s helpful to know about the types of electrical conduit available. Each type suits different environments, so choosing the right one depends on where and how you use it.

- Electrical Metallic Tubing (EMT): Lightweight and easy to bend, the EMT conduit is ideal for both indoor applications and commercial settings.

- Rigid Metal Conduit (RMC): Thicker and more durable, RMC is great for outdoor or industrial use.

- Galvanized Rigid Steel (GRC): Corrosion-resistant and strong, used in harsh environments.

- Intermediate Metal Conduit (IMC): A lighter alternative to RMC with similar strength, often used in commercial buildings.

- Flexible Metal Conduit (FMC): Allows flexibility in tight spaces, good for areas with vibration or movement.

- Liquid-Tight Flexible Metal Conduit (LFMC): Offers moisture protection, thus used in outdoor or damp environments.

- Electrical Non-Metallic Tubing (ENT): Easy to install and ideal for residential wiring.

- Rigid PVC Conduit: Common for underground installations, corrosion-resistant and, easy to work with.

- Non-Metal Electrical Conduits: Include plastic or composite materials for lightweight and corrosion-free applications.

- Rigid Non-metallic Conduit (RNC): Used in underground systems or corrosive locations.

- Reinforced Thermosetting Resin Conduit (RTRC): Durable and corrosion-resistant, often used in industrial setups.

- PVC Conduit: Lightweight, waterproof, and common in residential areas. It’s the grey pipe you see in basements or outdoor installs.

- Electrical Non-Metallic Tubing (ENT): Flexible and flame-retardant, ideal for indoor concealed wiring.

- HDPE (High-Density Polyethene) Conduit: Known for strength and flexibility, perfect for long runs or directional boring.

How to Choose the Right Electrical Conduit

Choosing the right conduit depends on several factors such as the location (indoor/outdoor), exposure (to water or chemicals), required durability, and flexibility. For outdoor use, metal or PVC electrical conduit works well. If flexibility is key, go for FMC or LFMC.

Also, don’t forget to consider code requirements and consult an electrician for larger projects.

Common Applications of Electrical Conduit

Electrical conduits are used in a wide range of environments:

- Residential Properties: To protect wires running in basements, attics, or through walls.

- Commercial Buildings: For structured wiring systems in offices or retail spaces.

- Industrial Setups: To handle high-voltage or exposed wiring that requires strong physical protection.

- Outdoor Installations: For garden lighting, underground wiring, or garage circuits.

Pros and Cons of Electrical Conduit

Like any system, electrical conduits come with both advantages and drawbacks. Here’s a breakdown:

Pros

- Waterproof Protection: Especially true for PVC and liquid-tight types.

- Neat Appearance: Keeps wiring organized and out of sight.

- Durability: Conduits extend the life of wiring systems.

- Easy to modify: Future upgrades or changes to wiring are easier.

- Reliable: Offers consistent performance across applications.

- Popular Choice: Trusted in residential, commercial, and industrial setups.

- Corrosion Resistance: Especially with PVC electrical conduit.

- Fire Safety: Reduces the risk of electrical fires.

- Shock Protection: Shields wires that could be dangerous if left open.

- Low Maintenance: Fewer issues once installed.

- Easy Replacement: Damaged cables can be replaced without redoing the whole system.

- Environmental Protection: Keeps wiring safe from chemicals, rodents, and moisture.

Cons

- Tough to Install: Requires planning, tools, and experience.

- Hard to Trace Faults: Once enclosed, it’s difficult to pinpoint wire issues.

- Can Be Expensive: Higher upfront cost than basic cabling.

- Time-Consuming Setup: Especially for large or complex systems.

- Shock Risk: Improper installation can still pose a danger.

- Future Changes are Tricky: Adding more wiring later can be a challenge.

- Less Aesthetic Than Hidden Systems: Especially with exposed PVC conduit.

- Susceptible to Damage: PVC conduits can crack under heavy pressure or impact.

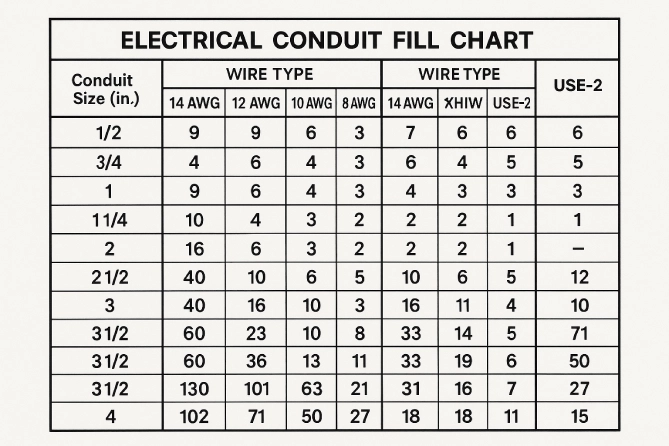

What is the Electrical Conduit Fill Chart?

An electrical conduit fill chart helps you determine how many wires can safely fit inside a specific size of conduit. Overfilling a conduit can lead to overheating and code violations. The fill chart accounts for wire size, insulation type, and number of conductors.

For detailed guidance, it’s best to refer to a full chart or consult an electrician. We recommend creating a separate resource page for this due to the high search volume.

Conclusion

So, what is an electrical conduit? In simple terms, it’s your wiring’s best friend, offering protection, organization, and peace of mind. Whether you are planning a new install or updating an older system, choosing the right conduit type matters more than most people realize.

And remember, when it comes to electrical safety, investing a little time in understanding these basics can go a long way.

FAQs

-

How deep should an electrical conduit be buried?

For metal conduits, a minimum depth of 6 inches below ground is the norm. If installed under a concrete slab, 4 inches is sufficient. For private driveways, the standard depth is 18 inches, while public roads require at least 24 inches.

-

Does an underground electrical wire always need a conduit?

Not necessarily. Direct burial cables are designed to go straight into the ground without a conduit. They are made with water-resistant insulation and can last for years when installed correctly.

-

How does a conduit work in electrical setups?

A conduit is basically a protective tube. It holds and shields electrical wires as they travel from one part of a structure to another. It protects both the cables and anyone who may come close to them.

-

What is a grey conduit used for?

Grey conduits, often PVC electrical conduit, are UV-resistant and typically used for outdoor electrical wiring. The color coding also helps distinguish it from conduits used for plumbing or other utilities.