When cool surfaces are exposed to warm, moist air, condensation occurs. Condensation is characterized by the cooling of surfaces after coming in contact with warmer air in their surrounding environment.

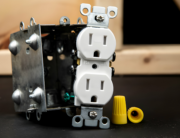

Electrical enclosures are prone to condensation, as they are exposed to temperature fluctuations. The remedy for this danger is the installation of thermal insulators, especially where electrical enclosures are installed outdoors.

When warm temperatures experienced in the daytime drop to lower degrees in the nighttime, condensation is bound to occur. This fact is aided by the rampant fluctuations in temperatures and extreme weather in the recent years.

Dangers posed by condensation

Perhaps the biggest danger posed by condensation is malfunction of electrical appliances. Since water vapor is trapped inside the enclosures, it causes corrosion or rusting of the metallic and electrical components.

The direct effect is breakdown of the electronic components, short-circuiting and premature deterioration of the entire appliance. Severe interruption of vital applications is often experienced.

How to prevent condensation

The use of heating, humidity and temperature control systems is perhaps the most effective method of checking the damage. Examples are thermostats, hygrothermsand hygrostats. When temperatures drop past a certain limit, a thermostat triggers heaters to turn on and avert danger.

On the other hand, a hygrostat triggers heaters when humidity rises past a set limit. A hygrotherm performs both functions. The only deterrent is the fact that the devices are usually costly.

A hygrotherm is the most intuitive of the three devices. It is ideal in parts of the world that experience extreme weather conditions. When air temperatures drop in winter, the device triggers heaters to generate the internal heat. In summer when humidity is high, the same device triggers heaters to lower the humidity. This effectively prolongs the life of electrical appliances.

Reasons to prevent condensation

There are four main reasons why you should be concerned about condensation in various compartments of electrical systems-

- Water collection in enclosure

- Blocked drains

- Water draining

- Risk of shock

-

- Water collection in enclosure

When the temperature falls below the optimal levels, condensation will occur on different components, even if there are condensate drains installed. The resultant corroding of components causes malfunctioning of moving parts, effectively rendering the whole electrical system useless!

- Water collection in enclosure

-

- Blocked drains

Even where enclosures have condensate drains, the installations are prone to clogging. This is especially true where the discharge pipes are laid on flat ground. When there is little or no condensation especially in dry seasons, dust and dirt usually collect in the pipes.As the foreign materials cause blockage of the drainage pipes, water accumulates on the drain pan. While condensation is bound to occur, the blockage causes problems such as corrosion of metallic pipes, necessitating expensive repairs. - Water drainingWhen condensation occurs, the water drips onto the floor. This is especially the case where collection drips are unavailable. The resultant effect is an undesirable water mess. This may cause employees to slip and fall.

- Risk of shock

All condensation on electrical appliances poses a risk of electric shock. This risk is especially prevalent where systems run at 240 to 480 volts. However, the shock is still prominent in systems running at 120 volts and in presence of excessive dampness.Anyone working with live equipment or testing electrical circuits is at risk. The remedy is installing effective systems that remove condensation. This ensures that no water condenses on the components or surface of the system.

- Blocked drains

Conclusion

A more effective approach to deal with condensate is installation of an air conditioner in the electrical enclosure. While it rids the moisture, it cools the surface. As the water condenses on the surface of the system, an evaporation system can boil it off. The result is effective maintenance of electrical systems with reduced energy usage.

D&F Liquidators has been serving the electrical construction materials needs for more than 30 years. It is an international clearinghouse, with 180,000 square facility located in Hayward, California. It keeps an extensive inventory of electrical connectors, conduit fitting, circuit breakers, junction boxes, wire cable, safety switches etc. It procures its electrical materials supplies from top-notch companies across the globe. The Company also keeps an extensive inventory of electrical explosion proof products and modern electrical lighting solutions. As it buys materials in bulk, D&F is in a unique position to offer a competitive pricing structure. Besides, it is able to meet the most discerning demands and ship material on the same day.